快速查找

主营塑料

产品推荐

- ⊕PPS OL003A 含玻璃纤维,聚四氟乙

- ⊕PBT 420SE0 玻纤30%增强,阻燃级

- ⊕PBT 310SE0 非增强型,PBT阻燃树脂

- ⊕PP HJ730 高流动,高钢性,高耐热

- ⊕PP FB71U6 耐热级,抗UV,阻燃级

- ⊕PA6 73G30L NC010 玻璃纤维30%增

- ⊕PA66 70G43L NC010 玻璃纤维43%增

- ⊕PA66 70G33L NC010 玻璃纤维33%增

- ⊕PA66 70G30L NC010 玻璃纤维30%增

- ⊕PA66 80G33L NC010 玻纤33%增强,

- ⊕PA66 FR50 NC010A 玻纤25%增强,阻

- ⊕POM 900P NC010 低粘度,热稳定,低

- ⊕POM 500P NC010 中高粘,热稳定,低

- ⊕POM 100P NC010 高粘度,韧性好,热

- ⊕PBT SK605 NC010 玻璃纤维30%增强

- ⊕PA66 1300G 玻纤增强级

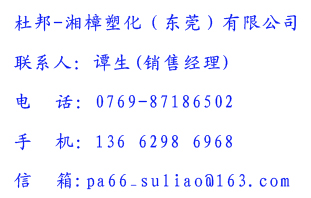

联系我们

DuPont™ Teflon PTFE 6C

fluoropolymer resin

Fine Powder Lubricated Extrusion Resin

Brand

Teflon® is a registered trademark of DuPont for its brand of fluoropolymer resins, which can only be licensed by DuPont for use in approved applica-tions. Customers who wish to use the Teflon® trademark in connection with DuPont Fine Powder products under license from DuPont should contact (86) 13662986968. Without a license, customers may not identify their product as containing Teflon®, but may refer to the resin as PTFE 6C.

Description

DuPont™ Teflon® PTFE 6C is a white powder composed of agglomerate particles. As with other grades of Teflon® polytetrafluoroethylene (PTFE) fine powders, it can be lubricated and extruded by pressure alone. This provides the capability for long lengths or products, such as tubing, and wire insulation, which cannot be melt extruded from PTFE resin.

Compared with other grades of PTFE fine powder, Teflon® PTFE 6C is a general-purpose resin. It is widely used for products with small cross sections requiring medium- to high-reduction ratio extrusions and fast processing rates.

Properly processed products made from virgin Teflon® PTFE 6C provide the superior properties typical of the fluoropolymer resins: retention of properties after service at 260°C (500°F), useful properties at –240°C (–400°F), chemical inertness to nearly all industrial chemicals and solvents, and low friction and antistick surfaces. Dielectric prop-erties are outstanding and stable with frequency and temperature. Products have moderate stiffness and high ultimate elongation.

In a flame situation, products of Teflon® PTFE 6C resist ignition and do not themselves promote flame spread. When ignited by flame from other sources, their contribution of heat is small and with very little smoke.

Statements, or data, regarding behavior in a flame situation are not intended to reflect hazards presented by this or any other material when under actual fire conditions.

Teflon® PTFE 6C is ASTM D4895, Type I, Grade 2, Class C (ASTM D1457, Type III, Grade 2, Class C).

Typical End Products

Applications for Teflon® PTFE 6C include reinforced hose for use with steam, hydraulic fluid, or reactive gas; electrical grade tape and sleeving; chemical linings and various other electrical and industrial products requiring extruded PTFE.

FDA Compliance

Properly processed products (sintered at high temperatures common to the industry) made from Teflon® PTFE 6C resin can qualify for use in contact with food in compliance with FDA Regulation 21 CFR 177.1550.

Processing

Teflon® PTFE 6C is prepared for extrusion by mixing with a liquid extrusion aid. The damp powder is compressed into a cylindrical preform slug and placed in the cylinder of a ram-type extruder. Under high pressure, the composition is forced through a finishing die to produce beading, tubing, or coatings. Dissimilar materials, such as metal wire or high-temperature fibers, can be coated by feeding them through the axis of the extruder barrel.

After extrusion, the product is a low-density, but coherent, fibrous structure. Teflon® PTFE 6C is usually processed further, with heat, into a solid resin product such as a tube.

Heat is applied in two steps, which may be taken in-line with extrusion or separately. The lubricant must be removed first, usually by heating within the range of 100–300°C (212–572°F). A sintering step follows to melt the virgin resin above its crystalline melting point of approximately 342°C (648°F) and produce a void-free, solid product of PTFE resin. When performed in-line, the heating steps determine the maximum line speed.

Reduction ratio (RR) is the ratio of cross section of preform to that of extrudate; it is an extruder option also affecting the selection of resin grade.

Safety Precautions

WARNING!

VAPORS CAN BE LIBERATED THAT MAY BE HAZARDOUS IF INHALED

Before using Teflon® PTFE 6C, read the Material Safety Data Sheet and the detailed information in the “Guide to the Safe Handling of Fluoropolymer Resins, Latest Edition” published by the Fluoropolymers Division of The Society of the Plastics Industry—available from DuPont.

Open and use containers in well-ventilated areas using local exhaust ventilation (LEV). Vapors and fumes liberated during hot processing, or from smoking tobacco or cigarettes contaminated with Teflon® PTFE 6C, may cause flu-like symptoms (chills, fever, sore throat) that may not occur until several hours after exposure and pass within 36 to 48 hr. Vapors and fumes liberated during hot pro-cessing should be exhausted completely from the work area; contamination of tobacco with polymers should be avoided. Mixtures with some finely di-vided metals, such as magnesium or aluminum, can be flammable or explosive under some conditions.

Flammable liquid extrusion aids can cause fires in ovens and in mixing areas. Before using, obtain manufacturer’s recommendations.

Storage and Handling

Teflon® PTFE 6C must be handled carefully to avoid shearing the powder prior to extrusion. Fibrillation by shearing is not reversible, and damaged particles can appear as defects in the finished product. As temperature is reduced, the powder becomes progressively less sensitive to mechanical damage or compaction in its containers.

Fine powder can withstand significantly more abuse when it is in the below room temperature transition state. For this reason, DuPont stores and delivers Teflon® PTFE 6C at or below 7°C (45°F). Teflon® PTFE 6C will remain in this cold transition state until it is warmed above 19°C (66°F). If this resin is allowed to go above 19°C (66°F) at any time, it must be cooled below about 10°C (50°F) to bring it back to the cold state.

All processing steps prior to preforming are facilitated at reduced temperature, but ambient dew point must be controlled to prevent condensation on the resin.

Storage and handling facilities should be clean. The high sintering temperature causes even very small foreign particles to become visible or to make defects in finished products. Keep resin drums closed and clean. Good housekeeping and careful handling are essential.

Table 1

Typical Property Data for Teflon® PTFE 6C Fluoropolymer Resin

| Property | ASTM Test Method |

Unit | Nominal Value |

|

| General | Bulk Density | D4895 | g/L | 460 |

| Average Particle Size | D4895 | µm | 480 | |

| Standard Specific Gravity | D4895 | - | 2.17 | |

| Rheometer Pressure* | D4895 | MPa(psi) | 51.7(7,500) | |

| Melting, Peak Temperature | ||||

| Initial | D4895 | (℉) | 342 (648) | |

| Second | D4895 | (℉) | 327 (621) | |

| Typical properties are not suitable for specification purposes. *Reduction Ratio 1600:1 |

||||

Freight Classification

Teflon® PTFE 6C, when shipped by rail or express, is classified “Plastics, Synthetic, O.T.L., NOIBN.” Resin shipped by truck is classified “Plastics, Materials Granules.”

Packaging

Teflon® PTFE 6C resin is packaged in 25-kg (55.1-lb) plastic containers.

聚四氟乙烯官网:http://www.pa66-suliao.com/product/gcsuliao/PTFE