快速查找

主营塑料

产品推荐

- ⊕PPS OL003A 含玻璃纤维,聚四氟乙

- ⊕PBT 420SE0 玻纤30%增强,阻燃级

- ⊕PBT 310SE0 非增强型,PBT阻燃树脂

- ⊕PP HJ730 高流动,高钢性,高耐热

- ⊕PP FB71U6 耐热级,抗UV,阻燃级

- ⊕PA6 73G30L NC010 玻璃纤维30%增

- ⊕PA66 70G43L NC010 玻璃纤维43%增

- ⊕PA66 70G33L NC010 玻璃纤维33%增

- ⊕PA66 70G30L NC010 玻璃纤维30%增

- ⊕PA66 80G33L NC010 玻纤33%增强,

- ⊕PA66 FR50 NC010A 玻纤25%增强,阻

- ⊕POM 900P NC010 低粘度,热稳定,低

- ⊕POM 500P NC010 中高粘,热稳定,低

- ⊕POM 100P NC010 高粘度,韧性好,热

- ⊕PBT SK605 NC010 玻璃纤维30%增强

- ⊕PA66 1300G 玻纤增强级

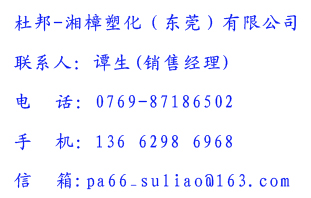

联系我们

DuPont™ Teflon® PFA 451HP

EXTRUSION AND MOLDING RESIN

Ultrahigh Purity: Special-purpose resin that offers the benefits of PFA 350 with the additional benefits of enhanced purity and improved thermal stability while processing. This resin has a relatively low flow rate, high flex life and enhanced resistance to environmental stress cracking. 451HP is a grade with improved surface smoothness achieved by minimizing spherulite size, and enhanced chemical permeation resistance.

Applications: Tubing; unsupported pipe or pipe linings for production of ultrapure chemicals; semiconductor component handling systems and fluid handling components.

Brand

Teflon® is a registered trademark of DuPont for its brand of fluoropolymer resins, which can only be licensed by DuPont for use in approved applications. Customers who wish to use the Teflon® trademark in connection with DuPont PFA products under license from DuPont should contact your local DuPont office. Without a license, customers may not identify their product as containing Teflon®, but may refer to the resin as PFA 451HP.

Description

Teflon® PFA 451HP fluoropolymer is a special purpose resin available in clear, 3.0mm pellets. This resin is a chemically modified form of Teflon® PFA 350 that combines many of the benefits of the parent resin with several new ones. The additional benefits are enhanced purity and improved thermal stability while processing. Similar to Teflon® PFA 350, this resin has a relatively low flow rate, high flex life and enhanced resistance to environmental stress cracking compared with most other grades of Teflon® PFA. Especially, PFA 451HP is a grade with improved surface smoothness achieved by minimizing spherulite size, and enhanced chemical permeation resistance achieved by increasing its crystallinity from PFA 450HP.

The enhanced purity of Teflon® PFA 451HP makes it suitable for applications that require improved color, lower extractable fluorides, and freedom from other foreign materials. This product contains no additives and is designed for hostile chemical environments where purity in the parts-per-billion range is needed. Examples are in semiconductor manufacture, fluid handling systems for industry or life sciences, and instrumentation for precise measurements of fluid systems. Teflon® PFA 451HP is preferred when extended service is required in hostile environments involving chemical, thermal, and mechanical stress. Table 1 shows the typical property data for Teflon® PFA 451HP.

The improved thermal stability of Teflon® PFA 451HP results in reduced amounts of bubbles in final parts and decreased corrosion of processing equipment. Teflon® PFA 451HP combines the processing ease of conventional thermoplastics with properties similar to those of polytetrafluoroethylene.

Properly processed products made from neat Teflon® PFA 451HP resin provide the superior properties typical of the fluoropolymer resins: retention of properties after service at 260°C, useful properties at –196°C, and chemical inertness to nearly all industrial chemicals and solvents. Dielectric properties are excellent. Molded products have moderate stiffness and high ultimate elongation.

In a flame situation, products of Teflon® PFA 451HP resist ignition and do not themselves promote flame spread. When ignited by flame from other sources, their contribution of heat is very small and added at a slow rate with very little smoke.

Typical End Products

Applications for Teflon® PFA 451HP include tubing; unsupported pipe or pipe linings for production of ultrapure chemicals; semiconductor component handling systems and fluid handling components.

Processing

Teflon® PFA 451HP can be processed by conventional melt extrusion and by injection, compression, and transfer and blow-molding processes. High melt strength and heat stability permit the use of relatively large die openings and high-temperature draw-down techniques that increase production rates. Reciprocating screw injection molding machines are preferred. Corrosion-resistant metals should be used in contact with molten resin. Extruder barrel should be long, relative to diameter, to provide residence time for heating the resin to approximately 395°C.

Table 1. Typical Property Data for DuPont™ Teflon® PFA 451HP Resin

| Property | ASTM Test Method |

Unit | Nominal Value |

|

| Thermal | Nominal Melting Point | D3307 | ℃ | 302–312 |

| Coefficient of Linear Thermal Expansion, | ||||

| 21-100℃ | D696 | mm/mm/℃(in./in./℉) | 14x10-5(9.2x10-5) | |

| 100–149℃(212–300℉) | - | mm/mm/℃(in./in./℉) | 18x10-5(9.7x10-5) | |

| 149–208℃(300–408℉) | - | mm/mm/℃(in./in./℉) | 22x10-5(12x10-5) | |

| Upper Service Temperature | - | ℃(℉) | 260(500) | |

| Flow Rate | D3307 | g/10 min | 2.0 | |

| Mechanical | Tensile Strength,23℃(73℉) | D3307 | MPa(psi) | 33(4800) |

| 200℃(392℉) | MPa(psi) | 18(2600) | ||

| Specific Gravity | D792 | - | 2.12-2.17 | |

| Tensile Yield Strength,23℃(73℉) | D3307 | MPa(psi) | 15(2,200) | |

| Ultimate Elongation,23℃(73℉) | D3307 | % | 360 | |

| 200℃(392℉) | % | 500 | ||

| Flexural Modulus,23℃(73℉) | D790 | MPa(psi) | 410(60,000) | |

| 200℃(392℉) | MPa(psi) | 54(7800) | ||

| Hardness Durometer | D2240 | - | D60 | |

| MIT Folding Endurance 0.20mm(0.787 in.) | D2578 | cycles | 5000* | |

| Electrical | Dielectric Strength Short Time,0.25 mm(0.010 in.) | D149 | kV/mm(V/mil) | 80(2,000) |

| Dielectric Constant,60-106 Hz | D150 | - | 2.03 | |

| Dissipation Factor,60-106 Hz | D150 | - | 0.0001 | |

| Volume Resistivity | D257 | Ωcm | 1018 | |

| General | Water Absorption,24 hr | D570 | % | <0.03 |

| Weather and Chemical Resistance | - | - | Outstanding | |

| Limiting Oxygen Index | D2863 | % | >95 | |

Note: Typical properties are not suitable for specification.

* Depending on fabrication conditions

Safety Precautions

WARNING!

VAPORS CAN BE LIBERATED THAT MAY BE HAZARDOUS IF INHALED.

Before using Teflon® PFA 451HP, read the Material Safety Data Sheet and the detailed information in the “Guide to the Safe Handling of Fluoropolymer Resins,” latest Edition, published by the Fluoropolymers Division of The Society of the Plastics Industry – available from DuPont.

Open and use containers only in well-ventilated areas using local exhaust ventilation (LEV). Vapors and fumes liberated during hot processing, or from smoking tobacco or cigarettes contaminated with Teflon® PFA 451HP, may cause flu-like symptoms (chills, fever, sore throat) that may not occur until several hours after exposure and typically pass within about 24 hr. Vapors and fumes liberated during hot processing should be exhausted completely from the work area; contamination of tobacco with polymers should be avoided.

Mixtures with some finely divided metals, such as magnesium or aluminum, can be flammable or explosive under some conditions.

Storage and Handling

Special product isolation and packaging procedures are used by DuPont to eliminate external contamination of Teflon® PFA 451HP resin. Processors also must avoid contamination for successful production of high-purity products.

The properties of Teflon® PFA 451HP resins are not affected by storage time. Ambient storage conditions should be designed to avoid airborne contamination and water condensation on the resin when it is removed from containers.

Packaging

Teflon® PFA 451HP is supplied as pellets and is available in 25kg multilayer kraft bags with an integral polyethylene liner.

PFA:http://www.pa66-suliao.com/product/gcsuliao/PFA